How do you improve your odds for long-term performance of a low-slope roof when standing water is a constant threat? At times, it is found that standing water is too difficult or too cost-prohibitive to correct, so you need this to be a constant consideration when designing your roof. It all comes down to the materials you trust to perform in these more adverse conditions.

Construction design and management can be very difficult when working in regions with four (4) climate seasons. To add a level of complexity, all too often, unreasonable construction schedules result in product and installation compromises, commonly hidden under the guise of “value engineering”. Value Engineering came about as a means to evaluate the use of other products or systems that may not have been in a project specification but were fully understood to be of equal or greater performance at a cost savings. Nearly all value engineering these days is simply a means to shave costs while being fully aware that the other products are not superior nor even equal; it is simply a guise to save money.

Use of the improper or inferior products or means of installation can lead to catastrophic results, especially when roof conditions are not ideal, such as plagued with standing water or other roof drainage issues. In this post, you will learn more about the different types of roofing materials and when it makes the most sense to consider choosing one versus another.

Four (4) Common Conditions to Understand Why Material Choice is Important for Low-Slope Roofing Projects

Drainage: Water Doesn’t Drain Properly on Flat or Near-Flat Roofs

A significant performance threat to a low-slope roofing system is that the water fails to flow freely from the roof surface, causing the water to stand. With pitches on low-sloped roofs commonly between ¼” to ½” per foot, gravity is not always enough to move water off the roof. Even with internal drains or scuppers, you may still get localized ponding after every storm due to improper sizing and placement of drainage outlets.

You need a fully waterproof membrane that performs under constant moisture and UV exposure. Your best options include:

- Torch-applied APP and SBS modified bitumen systems

- Self-adhered SBS membranes

- Cold-adhered SBS modified bitumen systems

- Liquid-applied waterproofing systems

Polyglass’ Elastoflex membrane systems are multi-ply SBS membranes available in grades to heat-fuse with a torch, bond with hot asphalt or cold adhesives, as well as self-adhesive systems. Though most Code requires the roof to have drainage, sometimes the best plans do not work out well, and standing water can result. Polyglass’ Elastoflex membrane systems are robust and can perform even under the most challenging roof conditions. Most Polyglass membrane systems can perform in conditions that could have drainage challenges; the self-adhesive systems should be limited to those with positive drainage.

When conditions are impossible or cost-ineffective to remedy, such ponding water conditions could be very detrimental to some roof types. If the slope-to-drain layout is marginal, you may find it necessary to have materials that can tolerate ponding. In isolated areas, such as in proximity to drainage or other sensitive conditions, it may be necessary to reinforce these isolated locations with our Polyflash 1C or PMMA liquid-applied systems that cure into one unified, ponding-resistant barrier.

UV, Heat, and Foot Traffic Put Extra Stresses on Low-Sloped Roof Systems

Without the benefit of steep pitches, overhangs, or natural water runoff, low-sloped roofs absorb full sun exposure all day long and all too often are used as a work platform for other work on or around the roof.

SBS-modified bitumen membranes are highly recommended here as they can resist such and rebound without cracking. If your project is in California, Arizona, Texas, or the sunbelt region, UV resistance is a constant. Look for granule-surfaced cap sheets or add a bright white elastomeric or PMMA topcoat to reduce heat absorption and extend the lifespan of the roof.

Use reinforced membranes (e.g., Polyglass’s Elastoflex SA V or SA P) to avoid scuffing, tearing, or compressing weak spots from people walking directly on them. These membranes make ideal walk pads or sacrificial surfacing layers to protect the primary membrane.

Rooftop Penetrations Are Where Most Roofs Leak

It’s rarely the field membrane of an installed roof system that experiences leaks first. The more challenging points are almost always the curbs, vent pipes, skylights, drains, and conduit supports. These are the areas where your material system gets put to the test, and where the wrong product or sloppy detailing can result in leakage and premature roof replacement.

Because every time you shift from horizontal to vertical — like flashing around an RTU curb or plumbing vent — you’re susceptible to a potential failure point. Proper use of materials and installation practices is critical to the best performance of any roof.

Where fire safety is a heightened consideration, self-adhered membranes in combination with liquid-applied flashing materials are worth considering in these situations. Polyglass’s ADESO® technology uses a dual-compound membrane: one side bonds cold to the deck or vertical substrate, while the other self-seals and welds into the cap sheet above. Around curbs or clusters of pipes, PMMA liquid systems (like Polyglass’s Polyflash 1C) are recommended. You may want to use pre-formed boots or field-molded flashings for vent pipes and penetrations.

Climate, Code, and Jobsite Conditions

The reality is that no two low-slope roofing jobs are alike. Even if the roof design is similar, the environment it exists in and the conditions you are working under can completely change what materials make sense.

Building Codes, be it for Non-Residential or Residential building types, the Code is relatively clear on its requirements for resistance to Fire, Wind, Seismic, and Impact. Take wind zones, for instance, in coastal regions or hurricane-prone areas, these locations often require greater resistance to wind displacement. Most Authorities Having Jurisdiction (AHJ) will require simulated testing for these conditions, such as FM 4470 or similar. Edge securement in the Code is clear in that all metal flashing is to be ANSI/SPRI/FM ES-1 compliant.

The freeze-thaw durability can be an important consideration in colder climates, such as Climate Zones 5 and higher. Roofing materials here must stay flexible even when temperatures drop from day to night. SBS-modified membranes are a wise choice because they maintain elasticity in freezing temperatures and resist cracking or splitting. This also holds for polymer-modified underlayments for steep slope roofs, which can add significant service life to nearly every steep roof covering system.

There is always concern when the subject of fire comes up. Any structure, be it residential or non-residential, must have a roofing system that has a tested fire classification. Occupancy will dictate the requirements from Class C as the least stringent to Class A as the most stringent. Remember, fire classifications include all building and roof components when testing.

How to Choose the Right Roofing System for Your Low-Slope Project

Modified Bitumen Membranes

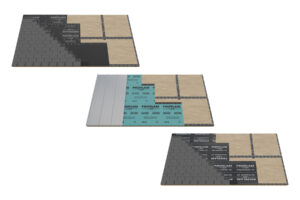

When you want your low-slope flat roof to hold up against weather, wear, and time, multi-ply modified bitumen (mod-bit) systems are still one of the most trusted options in the industry. Polyglass makes both SBS and APP-modified bitumen membranes, each reinforced with polyester or fiberglass scrims to boost strength.

SBS (Styrene-Butadiene-Styrene) membranes stay flexible in harsh freeze-thaw cycles or intense UV exposure. That makes them perfect for roofs with dynamic movement around HVAC curbs, expansion joints, or settling substrates. APP (Atactic Polypropylene) membranes are more resistant to UV and higher temperatures. They’re excellent in high-heat areas with lots of sun, but not the best choice if flexibility is colder temperatures are critical.

If your roof includes mechanical zones, solar installations, or anywhere service crews regularly use the roof as a work platform, multi-ply SBS and APP membranes have a historic track record of being the best option. In the highest traffic areas, consider adding a walkway system or a UV-reflective PMMA coating over wear-prone areas.

Self-Adhered Membranes

Self-adhered assemblies are best for sites with torch restrictions or other fire restrictions. By removing the need for open flame torches and hot asphalt, they allow you to improve crew safety and accelerate timelines without compromising on membrane quality and installation.

Polyglass’ ADESO® membranes are built with a dual-compound design. Having a membrane with full mat saturation and compound above and below the reinforcing mat is the ideal membrane design. Adding an adhesive layer to the bottom, resulting in a self-adhesive system, offers unique characteristics and safety. All you need to do is roll and press down. These systems are ideal for sensitive sites like schools and hospitals. Since there’s no open flame, you can install right up to walls, parapets, and curbs without special permits or fire watches. To get a watertight, multi-layer assembly that can go down in a single day, consider pairing one or more layers of our SA base Elastoflex SA V as the base layer(s), with Elastoflex SA P as the cap.

Elastomeric Coatings

If your roof is aged, elastomeric coatings can often provide years of extra service life without the cost and disruption of a full tear-off. Coatings, with and without reinforcing polyester, can be installed over existing membranes (mod-bit, metal roofing, TPO, etc.) to seal cracks, restore UV reflectivity, and form a new weatherproof layer. Polyglass offers a complete line of liquid-applied products to suit and project conditions.

- PolyBrite 70: 100% acrylic, water-based elastomeric roof coating for roofs with positive drainage

- PolyBrite 90: Moisture‑cure silicone, high-solids coating for roofs with ponding, freeze-thaw, or wide temperature swing issues.

Silicone holds up better under ponding water; acrylic gives you better reflectivity at an affordable price, but may degrade if water sits too long. You can reinforce these coatings with primer and fabric (sealing up to 1/8″ gaps).

Liquid-Applied PMMA and PU Systems

When your new roof layout has a lot of tight corners, vertical transitions, or pipe clusters, liquid-applied systems are generally hard to beat. Polyglass PMMA systems use a two-component, cold-applied resin that forms a fully bonded, UV-resistant membrane over concrete, metal, and existing bitumen substrates.

They cure quickly (within an hour under optimal conditions), stay flexible in cold temperatures, and chemically bond to the substrate (no fasteners or welding needed). You can use Polyflash 1C (silane-modified polyurethane layer) to reinforce curbs, drains, and dish-shaped penetrations over your main membrane.

Vapor and Air Barriers

Don’t let interior moisture from building occupancy, kitchens, pools, or HVAC systems migrate up into your roofing system. Once it meets a cold roof deck, the condensation will degrade adhesives, corrode metal, or cause mold growth. Vapor diffusion retarders stop the warm indoor air from reaching the cold roof decks and wreaking all of that damage.

Polyglass offers PolyVap SA S, a self-adhering air/vapor barrier for low-sloped roofs. It’s a carrier-less membrane that bonds directly to metal, OSB, plywood, or gypsum without primer. It also serves as a temporary dry-in layer for up to 180 days. It can be installed at temperatures as low as 20°F and doesn’t require open flame or hot asphalt.

Hybrid Systems

There’s no rule saying you have to use only one approach. You can get the best of all worlds (speed, safety, and long-term performance) with a combination of products. For example, start with a self-adhered base sheet (for fast, flame-free dry-in), then add a torched or cold-applied cap sheet to meet durability or fire resistance specs. Or reinforce weak areas on retrofit projects with liquid-applied flashings or elastomeric coatings without a complete roof replacement. If you’re not sure how to mix and match products, reach out to Polyglass today.

Contact us to Learn More About Polyglass Solutions for Your Roofing Project

You have to think beyond the building codes and warranties when designing and installing a low-slope roofing system. Every layer of membrane, base sheet, adhesive, insulation, and surfacing must work together to outlast storms, foot traffic, solar radiation, and aging infrastructure.

If you have ever had a membrane failure due to poor vapor control or watched a coating delaminate from thermal cycling, you already know the stakes. And yet, with so many new products on the market today from different roofing materials manufacturers, the decision process is only getting harder.

Our technical sales representatives are here to help. Whether you are re-roofing a retail strip mall or designing a residential roof, let us show you how Polyglass systems adapt to what your job demands.