A lot of the problems you see with a low-sloped roof (no roof is truly flat) that was installed years ago begin during the design or construction phase itself. Sometimes the drains are installed in the wrong location, not enough slope is built into the structure, or the poor-quality insulation flattens out over time.

All of these issues are entirely avoidable with proper planning done ahead of time. However, when the focus is on building a roof that meets the relevant codes, rather than one that will last for decades, problems are sure to arise. Most codes don’t even require slope if the roof can technically drain. When your drainage systems rely heavily on gravity or perfectly clean scuppers, ponding is bound to happen.

What is Ponding Water on a Flat Roof?

The word “ponding” refers to when water (usually from rain) pools up on the roof and stays there even 48-72 hours. The puddles don’t drain off because something is blocking the drainage path.

The longer this water stands instead of flowing off, the more damaging it becomes to the roofing material quality. It reacts with the roof membrane and wears out the asphalt (and other materials) faster. Asphalt (in BUR and Modified Bitumen roofing), bitumen coatings, insulation boards, plywood, fiberboards, sealants, and flashing compounds all need dry-out cycles. If the roof stays wet for long periods of time, these components lose their chemical adhesion and structural integrity.

That’s not all. Water absorbs the infrared radiation from the sun. So, the waterlogged areas remain hotter for several hours even after the sun goes down. The prolonged exposure to heat further accelerates the wear and tear of asphalt and any surface coatings.

Also, if the water is not removed in time, it collects dirt, leaves, twigs, bird nests, shingle granules, weed seeds, grime, and other small debris that bond with the roof surface. This is one of the most common culprits behind clogged drains, too, which makes the ponding worse. If the surface of the roof is slippery, the debris may have allowed algae or mold to thrive on there.

Facing so much deterioration on different levels, the lifespan of the roof is greatly reduced.

If the ponding gets deep enough, it adds hundreds or thousands of pounds of weight (depending on the size of the roof) to strain the structure. The roof might not collapse, but you will notice a lot of new roof leaks or fasteners coming loose.

What Causes Ponding on Flat Roofs?

The roof doesn’t have adequate slope

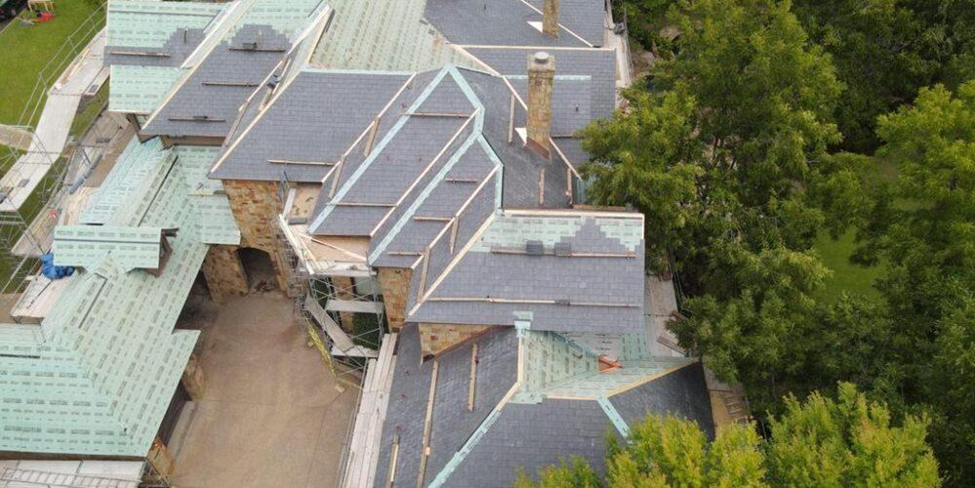

Despite the name, flat roofs are not level. They must have at least a minimum pitch of ¼ inch per foot to allow rainwater to drain quickly. Since the roof deck itself is flat, that slope is usually created using tapered insulation boards, which are angled to guide water toward drains or scuppers. These boards (e.g., polyiso) are cut at an angle to guide water toward drains, scuppers, and rain gutters.

But to reduce costs or installation time, some contractors install only flat insulation boards without adding taper. This creates areas on the roof where water has no clear path to evacuate. Even when angled boards are used, if they’re not properly designed to align with the drain layout, they will send runoff in the wrong direction.

In cases like these, where reworking the entire slope system is not feasible, you can use PolySlope. It’s a durable skim mortar specially made for creating a positive slope on ponding zones. PolySlope is fiber-reinforced for incredible strength, water-repellent, and designed for easy trowel finishing. It can be mixed onsite with water and applied to build smooth transitions toward drains/scuppers without tearing into the structure.

There are not enough drainage points

On a roof, drains must be spaced based on the roof area, expected rainfall intensity, and drain capacity (in GPM). For example, a single 4-inch drain might handle around 180-200 gallons per minute, but only if the slope actively directs water to it and it’s not clogged.

If a large roof only has two drains in opposite corners, rain that falls in the center or near the far edge will have no easy path to escape. There has to be a continuous pitch leading that way. Each internal drain, scupper, or gutter can only handle a certain volume of water. If you don’t have enough of them spread out across the surface, water will pond in areas that are too far from the nearest exit point.

The roof has too much deflection

When a roof is not built with enough support, or it has aged and started to settle, water will find those dips/depressions and stay there. Deflection refers to the downward bending or sagging of the roof structure under the weight of the roofing system itself, HVAC units, foot traffic, or snow, rain, or ponded water. If these loads get too heavy for the roof, parts of the deck start to bend down between joists, beams, or supports.

On a sagging roof deck, water naturally flows into the low points. If the slope is minimal to begin with (as it is on flat roofs), even a small deck deflection can be enough to trap water.

Crickets are missing

If your flat roof has big mechanical units or skylights and no crickets behind them, ponding is inevitable. We are not talking about the insects, but the triangular-shaped sloped backing that’s installed on flat roofs to divert the water toward drains instead of letting it get stuck behind the HVAC units, skylights, chimneys, pipe clusters, wall transitions, and roof access hatches. Every large curb needs a cricket to make sure the rainwater doesn’t get trapped behind it.

How To Prevent Standing Water

First things first, make sure there is positive sloping towards the drains. The industry standard is at least 1/4 inch per foot, though some contractors go with 1/8 inch in certain cases. But for areas that get heavy rainstorms or snow melt, 1/8” is not enough. Use rigid insulation boards that are pre-cut at an angle to create a slant under the membrane.

Once you have taken care of this basic design aspect, only then move on to the next steps:

Drainage design

If you want to prevent ponding on the roof, you have to start with the positive drainage planning before laying anything down. You know water will always go somewhere, so your job is to control that path.

Consider building internal drains with scuppers or overflow systems into the roof and connecting them with the plumbing. Place them at the lowest points of the roof (valleys created by the slope). You can also lower the insulation or deck level slightly at drain locations to create a bowl shape (tapered drain sumps) that funnels water directly into the drain. To prevent flooding during extreme rain, install backup/overflow drains higher up than the main drain. If the primary drain gets clogged, water can still escape.

Rooftop equipment placement

A lot of ponding issues happen because someone put a large HVAC/solar unit, skylight, or parapet wall in the wrong spot, or didn’t account for what it would do to drainage. Water gets trapped behind or around these structures. To prevent this, install crickets/saddles behind them, and use raised curbs and flashing to keep water away from seams. Leave plenty of clearance around equipment so water can move freely, avoiding placing units in areas that are naturally lower than the surrounding roof.

Membrane installation

Even if the slope and drainage are perfect, if your roof membrane system fails, water is going to find its way underneath. And the #1 place membranes fail is at the seams. Seams are where two rolls of membrane meet. Unless they are bonded tightly and water-resistant, water runoff will sneak in, causing blisters, delamination, leaks, and rot.

The membrane must be fully adhered across the entire surface (not only spot-bonded or tacked down at the seams). Any air gaps or loose layups may result in sagging, bridging, or membrane flutter when water starts to pool. Use a two-part adhesive (low-rise foam or bonding adhesive), rolled or sprayed evenly across the deck.

Polyglass offers a wide range of modified bitumen roofing membranes, including both APP and SBS systems, to match different installation methods and climate demands. Many of these are built with ADESO® self-adhered technology to help ensure an even bond with 100% coverage and no trapped air pockets; you will never have to worry about any sagging or separation down the line.

If the building is in a wildfire-prone area, Polyglass’ Elastoflex® SA V FR, Polyflex® SA P FR, and Polyfresko® G SA FR membranes are worth looking into. These products are CAL FIRE-approved, featuring the Burn Shield® Technology, and listed for use in WUI (Wildland-Urban Interface) zones.

If the roof has multiple elevation changes or transitions (e.g., over tapered insulation), take extra care to embed the membrane snugly over those contours so it doesn’t lift later.

Roof coatings

In areas where minor ponding is unavoidable (e.g., around rooftop units or shallow dips), roof coatings can be a smart way to protect your system.

These are fluid-applied products that go over the membrane either as a restoration system to extend the life of an older roof or a reinforcement for spots with minor ponding that can’t be re-sloped easily. Coatings are especially helpful on older roofs when you are not ready to replace them but still want to reinforce the weak spots and buy more time.

Although coatings do not eliminate ponding, some products can help protect the roof membrane in shallow depressions, areas behind rooftop units, or low points that are vulnerable to standing water. But they only work if the roof is otherwise stable and if the product is rated for use in ponding conditions.

Polyglass offers silicone-based and elastomeric coatings — including PolyBrite® 90 and 95 — that are formulated to provide protection against stagnant water. If you are looking for the best roof coating for ponding water, look no further. PolyBrite® silicone coatings are resistant to extreme weathering and come with a 50-year limited warranty!

To make these coatings last even longer, use Polyclean™ to strip away dirt, grease, and algae before application. A hybrid sealant like PolyFlash® MPS should be applied for flashing edges and penetrations; it bonds extremely fast, even in damp areas, and stays watertight in ponding zones.

That said, coatings only work if the rest of the roof is in decent shape. And not every product can handle standing water. You’ll want a system that’s rated for ponding conditions and built to last.

Preventive maintenance

If ponding tends to collect around the area where a pipe curb or solar rack sits too low, consider rebuilding that curb entirely. The PolyFlash® Flexible Curb Kit makes it easy to create a customized watertight barrier that prevents moisture from sneaking into the irregular penetrations.

Whenever you notice any amount of water standing on the roof after a storm, and it doesn’t evaporate or drain within two days, call in a professional roof inspection and repair crew. The longer water sits, the more time it has to find a way in. Also, you could lose your roofing warranty if you ignore it. Most major roofing manufacturers clearly state in their warranty documents that coverage excludes damage caused by water ponding for a certain consecutive hours.

Experienced roofing repair experts can quickly diagnose the cause of ponding water on the roof, pinpoint all the problem zones, and repair them immediately.

Need Help Designing Your Flat Roofing System?

Polyglass offers jobsite support and training for contractors installing roofing systems in areas where ponding water is a concern. From full-surface adhered membranes to coatings that can withstand water stagnation, our reps are here to help you build in long-term water control without blowing the budget. Contact us to learn more.