Artistic Roof and Design is a leading commercial and industrial roofing company serving the Fresno, California area for more than 20 years. A family-owned business focusing on quality, this company stakes its reputation on providing outstanding service and workmanship with every project they undertake. So when Southern California Edison (the main electrical utility company for the region) contracted Artistic Roof and Design to install a new roof for their Big Creek Hydroelectric Powerhouse on the San Joaquin River, they naturally chose Polyglass as their waterproofing solution of choice.

Project Needs and Challenges

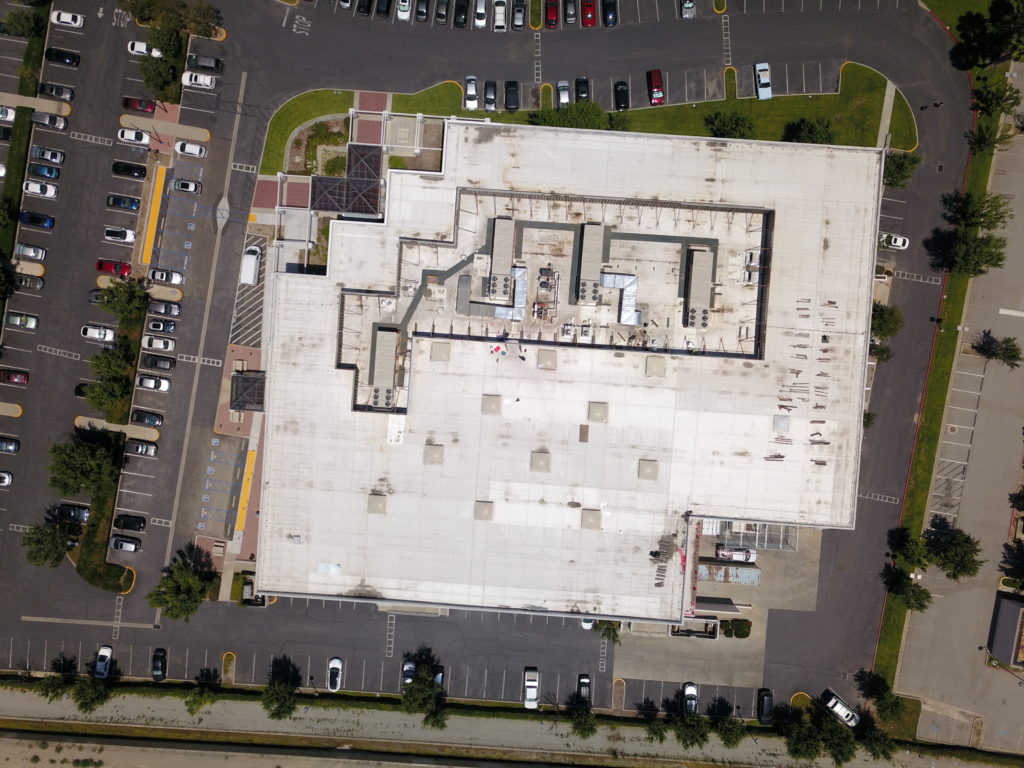

According to lead contractor Kevin Robinson, temperature and moisture presented the two greatest challenges to this installation project, encompassing 235 squares. “The foam is highly sensitive to temperature and moisture, making this a very hard job to do during this time of year,” said Robinson. “The average 8 am temperature on the job was 28 degrees [Fahrenheit]; this being a hydroelectric powerhouse, we [also] had to deal with constant moisture in the air.”

To overcome these challenges, the team started by priming the substrate with PolyBrite® 780, a black, water-based epoxy primer designed to absorb radiant heat from the sun for better bonding of the spray polyurethane foam. After installing the foam layer, they applied a second layer of PolyBrite 780 to add adhesion to the foam and prep the surface for the polyurea layer and waterproof roof coatings to follow.

The roofers finished the surface with Polyglass PG 700-QS (1.5 gallons of grey and 2.5 gallons of white). PG 700-QS is a quick-setting elastomeric coating typically applied to provide resistance to early rain exposure. In this case, it was used to seal the SPF foam against the constant moisture emitted by the powerhouse itself.

Polyglass Product Spotlight

Artistic Roof and Design utilized the following Polyglass products to meet the unique challenges of installing a foam roof on a hydroelectric powerhouse in cold temperatures:

- PolyBrite® 780 – a black, water-based epoxy primer/sealer that improves the adhesion of spray polyurethane foam to a wide range of roofing materials.

- PG 700-QS (grey and white) – a quick-setting water-based elastomeric coating that cures to form a seamless, “cool roof” UV-resistant membrane over the entire roof surface.

- PolyBrite® 73 flashing compound – a premium-grade UV-resistant white elastomeric mastic used for flashing and detail in conjunction with Polyglass’ elastomeric roof coating systems.

Polyglass is a well-known market leader in delivering cutting-edge solutions for the commercial roofing sector, offering a comprehensive range of high-quality goods tailored to suit roofing needs of all types. Polyglass now offers high-performance and exceptional quality Building Envelope Solutions.

For more information on our product lines, contact us here.

“Over the last 44 years, we have roofed and re-roofed the same buildings for our clients since we opened,” says owner Rick Wilson. “They are not only happy with our quality re-roof work, but our clients are also very pleased with our guaranteed roof maintenance and repairs.”

“Over the last 44 years, we have roofed and re-roofed the same buildings for our clients since we opened,” says owner Rick Wilson. “They are not only happy with our quality re-roof work, but our clients are also very pleased with our guaranteed roof maintenance and repairs.”

Air-Sea Forwarders is an air and ocean import/export company that also administers warehousing solutions for businesses on a global scale. One of the warehouses they utilize in Southern California was in need of complete reroofing due to deterioration of the original cap sheet.

Air-Sea Forwarders is an air and ocean import/export company that also administers warehousing solutions for businesses on a global scale. One of the warehouses they utilize in Southern California was in need of complete reroofing due to deterioration of the original cap sheet.