Gentech Roofing is a family-owned business that has served the industrial and commercial roofing needs of the Greater Toronto Area for more than 35 years. As winners of the Toronto Star Reader’s Choice Award in 2018 and 2020, they have built a solid reputation in the community for bringing stellar workmanship and service to every project they undertake. When Stonegate Dental in Guelph, ON, contracted Gentech to install a new roofing system on their facility, it came as little surprise that Polyglass was their product line of choice.

Project Needs and Challenges

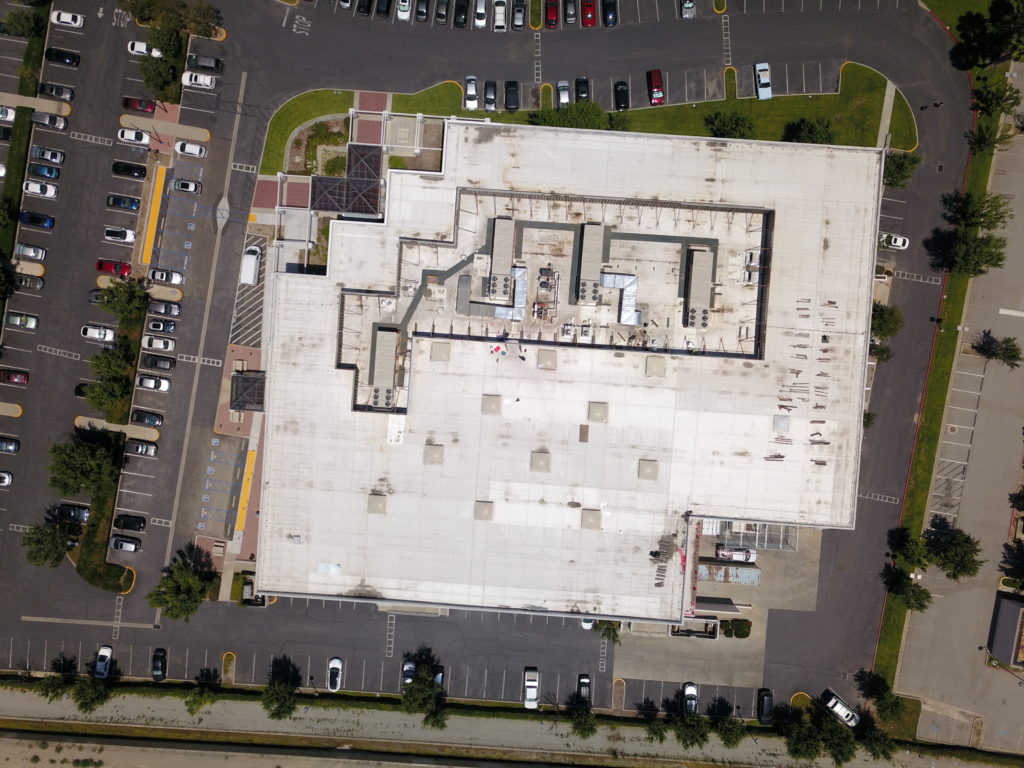

Embarking this project, Gentech faced the challenge of tearing out the old 4-ply BUR roofing system and laying down a new waterproof layer in a short amount of time. They also needed to minimize their impact on the dental office and other tenants who needed to continue conducting business while construction was underway.

To meet these challenges, Gentech installed Polyglass’ Stick 1 Torch 1 roofing system, a 2-ply modified bitumen system consisting of a self-adhered (SA) Elastoflex SA base sheet and a torch-applied Elastoflex S6 G 4.0 HP cap sheet installed over 2-inch ISO boards. Thanks to its ability to adhere directly to the ISO board with minimal effort, the Gentech workers could quickly apply the single-ply base sheet layer to make the roof watertight while allowing tradespeople to carry on work inside the building below. This quick installation reduced the total man-hours for the install by at least an hour and a half for each man.

Watch the Polyglass time study to see the labor-saving benefits of the Stick 1 Torch 1 system when compared with a 2-ply torch-applied roofing system:

The Stick 1 Torch 1 roofing system also allowed for a much cleaner and less intrusive roofing installation, with no asphalt ribbons, no over pours, and no strong odors to inconvenience Stonegate Dental’s patients. For the Gentech contractor on-site, the installation’s primary benefit was its safety as the Stick 1 Torch 1 system does not need hot asphalt for its application. He also found it to be more cost-effective, with no need for propane or the hiring of additional resources to operate the asphalt kettle.

Polyglass Product Spotlight

Gentech utilized the following Polyglass products with the Stick 1 Torch 1 system installed on the Stonegate Dental building:

- Elastoflex SA Base is a flexible yet highly tear-resistant modified bitumen membrane featuring ADESO® dual-compound self-adhering technology and finished lay lines for easy and accurate installation. When used in conjunction with an approved Polyglass cap sheet, Elastoflex SA Base provides exceptional waterproofing properties. It allows for a fast and clean installation without the need for torches, hot asphalt, or separate bonding adhesives.

- Elastoflex S6 G 4.0 HP is a high-performance Styrene-Butadiene-Styrene (SBS) cap sheet ideal for multi-layer low-slope roofing assemblies. When used as part of a high-quality multi-ply roofing system, it adds a strong layer of waterproofing and can be easily applied to the base via torch heat welding or cold adhesives.

Polyglass leads the industry providing innovative solutions for commercial roofing contractors. They feature a broad line of high-quality products designed to accommodate a full range of roofing systems and a wide variety of challenges. To learn more about how our products can benefit your next commercial roofing project, contact us here.

Located in Edgartown, MA,

Located in Edgartown, MA,

Located in Ocean City, MD, Triton’s Trumpet is a resort-style condominium complex located by the beach, highly popular for vacation rentals. When Tropical Storm Isaias hit the area on August 4, 2020, the storm blew off half the roof of one building and significantly damaged the roof of another.

Located in Ocean City, MD, Triton’s Trumpet is a resort-style condominium complex located by the beach, highly popular for vacation rentals. When Tropical Storm Isaias hit the area on August 4, 2020, the storm blew off half the roof of one building and significantly damaged the roof of another.

“Over the last 44 years, we have roofed and re-roofed the same buildings for our clients since we opened,” says owner Rick Wilson. “They are not only happy with our quality re-roof work, but our clients are also very pleased with our guaranteed roof maintenance and repairs.”

“Over the last 44 years, we have roofed and re-roofed the same buildings for our clients since we opened,” says owner Rick Wilson. “They are not only happy with our quality re-roof work, but our clients are also very pleased with our guaranteed roof maintenance and repairs.”