Maxx Leverage Roofing & Restoration is a licensed roofing company with over two decades of experience operating out of Idaho, Oregon, Florida, Louisana, and Alabama. This veteran-owned company offers roof repairs, reroofing, and roof replacement services for residential and commercial properties and specializes in emergency disaster relief for survivors needing temporary roofing and tree and debris removal.

When Maxx Leverage contractor and long-time Polyglass customer, James Moore, learned about Polyglass’s Polystick® XFR roof underlayment at a Polyschool session last April, he was so impressed with the product’s innovative qualities he chose to use it for his next big project in Miami, FL.

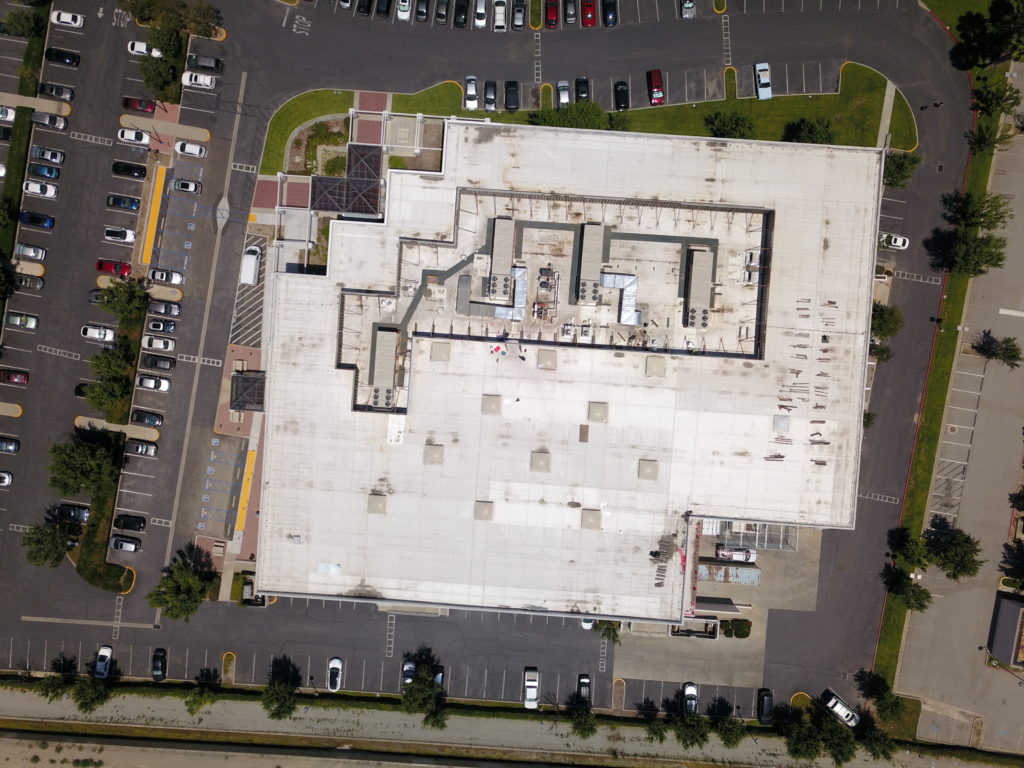

This contract was the Hyatt House Miami Airport Hotel in South Miami, Florida, requiring over 30,000 square feet of new roof underlayment. A perfect opportunity for James to put Polyglass’ dual-purpose, fire-resistant, and self-adhered waterproofing underlayment to the test!

“The contractor chose the superior protection of the Polystick XFR self-adhered (SA) underlayment waterproofing system. XFR was selected for the advanced Burn-Shield Technology™ with maximum fire-resistance properties delivered in one single layer installed as part of the metal roof assembly (unlike conventional fire barrier systems requiring a secondary fire barrier to achieve the UL Class A Fire Rating for Combustible Decks). Polystick XFR qualifies for up to a 30-year warranty backed by the Polyglass protection guarantee.”

John Massengill – Independent Sales Representative for Polyglass

Polyglass Product Spotlight

Polystick XFR utilizes ADESO® dual-compound self-adhered technology for efficiency and ease of application and patent-pending Burn-Shield Technology for superior fire resistance.

Polystick XFR’s slip-resistant film surface can be exposed for up to 180 days. With a temperature resistance of up to 265°F, Polystick XFR is ideally suited for high-temperature systems such as steel and copper roofing. Polystick XFR helps achieve a UL Class A Fire Rating in a single layer instead of typical solutions requiring multiple layers.

Watch the Polystick XFR fire reaction test video to see how Polystick XFR outperforms competitor underlayments in a fire reaction test.

Polyglass celebrates 30 years of cutting-edge product innovation for the U.S. building and waterproofing industries, featuring a broad line of premium roof coatings and roof maintenance systems for commercial roofing contractors. Evolving through innovation, Polyglass now offers high performance and exceptional quality Building Envelope Solutions.

Contact us here to learn more about how our products can benefit your next commercial roofing project.

Located in Edgartown, MA,

Located in Edgartown, MA,

Located in Ocean City, MD, Triton’s Trumpet is a resort-style condominium complex located by the beach, highly popular for vacation rentals. When Tropical Storm Isaias hit the area on August 4, 2020, the storm blew off half the roof of one building and significantly damaged the roof of another.

Located in Ocean City, MD, Triton’s Trumpet is a resort-style condominium complex located by the beach, highly popular for vacation rentals. When Tropical Storm Isaias hit the area on August 4, 2020, the storm blew off half the roof of one building and significantly damaged the roof of another.