By Steven C. Wadding RRC, RRO, CDT, Corporate Projects Manager, Polyglass USA

Image: Courtesy of Atlas Consulting

The Chet Holifield Federal Building is more than just an architectural landmark; it symbolizes resilience and innovation in roofing technology. For those familiar with Architectural West magazine since 2004, you may recall the March/April cover story featuring a stepped-pyramid building in Laguna Niguel, CA—the Chet Holifield Federal Building. Originally constructed in 1970 for Rockwell International, the building was designed by the visionary architect William L. Pereira (1909-1985). In 1997, it became a valuable asset for the General Services Administration (GSA), showcasing not just its architectural significance but also its enduring structural integrity.

A Historical Perspective: The Architectural Legacy

Image: Courtesy of Atlas Consulting

William L. Pereira’s design for the Chet Holifield Federal Building embodies the ideals of mid-century modern architecture, characterized by clean lines and a harmonious blend with the natural environment. The stepped-pyramid structure not only provides aesthetic appeal but also serves functional purposes, including effective water drainage and energy efficiency. Such foresight in design ensured the building could stand the test of time, both physically and conceptually.

When the GSA acquired the building, it recognized its potential to serve federal agencies and, subsequently, the public. This change in ownership marked the beginning of a new chapter in the building’s life, requiring updates and renovations to meet contemporary standards for safety, energy efficiency, and operational functionality.

The 2003 Renovation: A Roof for the Ages

In 2003, the Chet Holifield Federal Building underwent a significant renovation that included the replacement of its aging roof. Spanning 480,000 square feet, this project required careful planning and execution due to the sensitive operations housed within, such as the IRS and National Archives. These agencies demanded strict adherence to operational continuity, necessitating a roofing solution that would not disrupt their essential functions.

Western Roofing led the renovation project, partnering with CRC Consulting Group from Bakersfield, CA. Together, they faced a unique set of challenges, including the need for minimal noise, no fumes, and zero interruptions during the installation process. The roof replacement project required a careful balance of technical skill and consideration for the building’s occupants.

To meet these stringent requirements, Western Roofing Company turned to Polyglass U.S.A., Inc. for support. Polyglass provided its innovative polymer-modified low-slope self-adhesive membrane systems, designed to meet the GSA’s needs while ensuring that the installation process remained as quiet and unobtrusive as possible.

Innovative Solutions: The Polyglass Advantage

One of the key challenges during the roofing project was the existing roof deck’s near-zero slope. Traditional roofing systems often struggle with such low angles, which can lead to water pooling and, ultimately, leaks. To address this, the roofing contractors began with a clean roof deck and installed a tapered polyisocyanurate system. This system was bonded with low-rise foam adhesive, eliminating the need for thousands of fasteners. This approach not only streamlined the installation process but also enhanced the roof’s overall integrity.

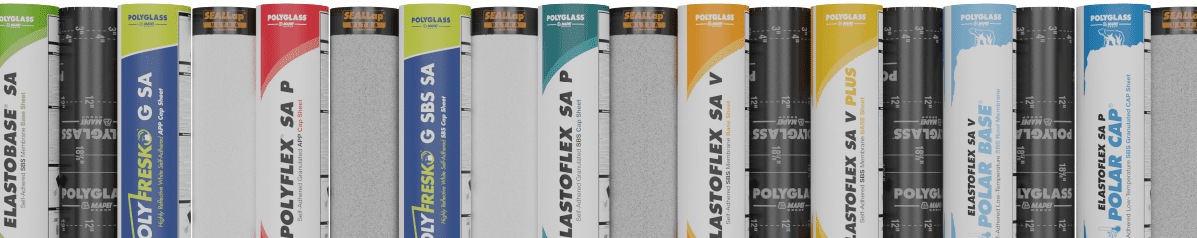

A cover board, also bonded with foam, was installed to create a stable surface for the roofing system. This innovative method set the stage for Polyglass’s two-layer system, consisting of the Elastoflex SA V base/interply membrane and Polyflex SA P APP mineral cap sheet. The choice of a buff-colored finish was not merely aesthetic; it helped reflect sunlight, contributing to energy efficiency while ensuring that the building remained dry and secure throughout the installation.

Western Roofing worked diligently to install the Polyglass self-adhered system while safeguarding the interests of tenants and the building’s valuable contents. My colleague, Rand McReynolds from the Technical Services Department at Polyglass, and I had the privilege of overseeing the project, providing support, and ensuring quality throughout the installation. The collaboration between Western Roofing, CRC Consulting, and Polyglass Technical Services was a resounding success.

The team delivered a watertight roofing system on time, within budget, and in full compliance with the GSA’s stringent requirements. The remarkable absence of tenant complaints throughout such a complex project was a testament to the team’s meticulous planning and execution.

A Long-Term Performance Review: Assessing Resilience

Fast forward to 2022, rumors began circulating that the GSA might sell the Chet Holifield Federal Building, as many of its federal tenants had relocated. Despite this, Polyglass’ Technical Services team had not received any complaints or warranty claims related to the roof. However, given the building’s potential transition, it was prudent to assess the roof’s condition. The team initiated discussions with building representatives to walk the roofs and document their status.

To assist in this endeavor, Polyglass enlisted Gary Weaver of Atlas Consulting. Weaver’s extensive background in roofing, particularly his skepticism of self-adhered membranes, proved invaluable during the evaluation process. He noted, “My experience with modified bitumen since the 1970s was great, but several of the self-adhered membranes I experienced in the early 2000s and up until this survey all seemed extremely problematic.” His insights brought a critical perspective to the assessment, especially as he embarked on reviewing the Polyglass SA membrane’s performance.

Upon visiting the site, the team observed that large sections of the roof had endured two decades of foot traffic, including workers installing an extensive rooftop solar panel system. Despite this wear, the roof’s remarkable resilience served as a testament to the quality of Polyglass SA membranes. Weaver’s positive assessment of the roof was particularly noteworthy, as it highlighted the longevity and durability of the roofing materials used.

In-Depth Evaluation: Testing and Results

To further assess the roof’s performance, Polyglass obtained permission to conduct a full qualitative assessment and quantitative testing of the roof. This comprehensive evaluation included bonded roof tests (ASTM D 3617), moisture detection through infrared thermography, and visual observations of multiple roof areas. The process was thorough, ensuring that every aspect of the roofing system was scrutinized.

Additionally, test cuts were taken from various parts of the roof and sent to Polyglass’ R&D labs in Deerfield Beach, FL. These samples underwent rigorous analysis for seam integrity (tested per ASTM D7349 & ASTM D6511) and close inspection of the various layers of the 20-year waterproofing material using a scanning electron microscope (SEM). The results were conclusive: the roof system continued to exceed performance expectations after 20 years of service, with Weaver confidently predicting a remaining life of another 30 to 35 years.

ADESO® Technology: Revolutionizing Roofing

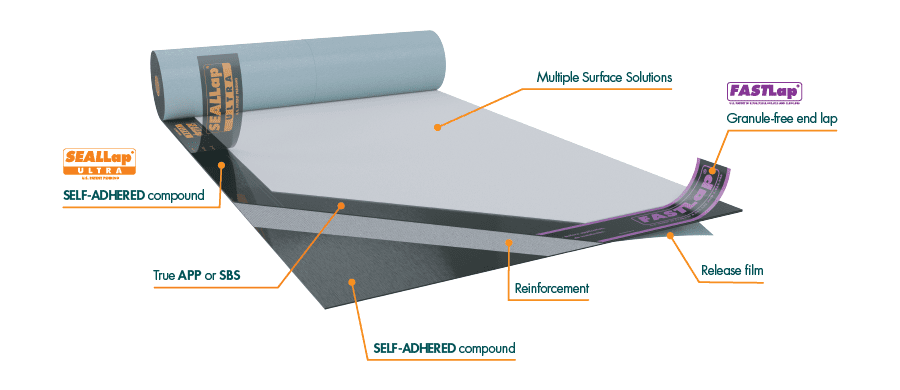

Coinciding with the monumental roofing project at the Chet Holifield Federal Building, Polyglass had developed and introduced ADESO® Self-Adhered Technology. This revolutionary application process for polymer-modified bituminous membranes eliminates the need for hot asphalt or mechanical fasteners. As a result, installations become faster, cleaner, and more user-friendly—transforming the way roofing professionals approach large-scale projects.

The success of the Chet Holifield Federal Building project serves as a powerful example of the durability and performance of Adeso® technology. After 20 years of exposure to the elements and significant foot traffic, the roof system continues to function flawlessly. This longevity underscores Polyglass’ commitment to providing innovative solutions that meet the evolving needs of the roofing industry.

A Lasting Legacy: The Endurance of Polyglass SA Membranes

For those who remain hesitant about polymer-modified self-adhesive membranes, the Chet Holifield project stands as a testament to their durability and reliability. After over 20 years, Polyglass’ revolutionary membrane system continues to stand the test of time, proving it is on par with, if not superior to, other commercial membrane systems.

The ongoing success of the roof at the Chet Holifield Federal Building not only reflects the quality of the roofing materials used but also the expertise and dedication of everyone involved in the project. From the architects to the contractors, each team member played a crucial role in ensuring the building remains a landmark of resilience and innovation.

As we look ahead, the lessons learned from the Chet Holifield project will continue to influence roofing technology and practices, driving further innovations in materials and installation techniques. With a legacy of performance and a commitment to excellence, Polyglass USA remains at the forefront of the roofing industry, ready to tackle new challenges and uphold the standard of quality established at the Chet Holifield Federal Building.

In conclusion, the Chet Holifield Federal Building is not just a testament to modern architecture but also a showcase of what can be achieved with innovative roofing materials and meticulous planning. The story of its roof is a powerful reminder of the importance of quality in construction and the enduring value of thoughtful engineering. Whether it’s maintaining the integrity of historic structures or innovating for the future, the principles demonstrated in this project will resonate for many years to come.