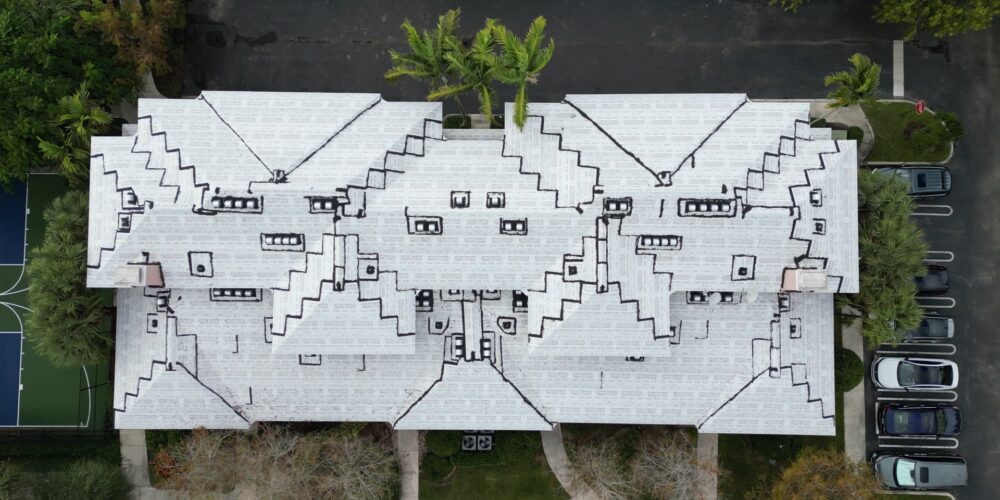

Cypress Pointe at Turtle Run in Coral Springs, Florida, is a premier community of 34 luxury townhomes that offers residents top-tier living with a range of premium amenities. Constructed in 2006, the homes recently underwent an essential roof replacement to withstand Florida’s unpredictable and often severe weather conditions. This critical upgrade was necessary to preserve the structural integrity of the buildings, improve energy efficiency, and boost overall property value. By safeguarding against leaks and water damage, the new roofing system reduces long-term maintenance costs, delivering homeowners lasting peace of mind and comfort.

Established in 1978, Best Roofing is dedicated to understanding client needs and building strong professional relationships. They provide a seamless, stress-free workflow, delivering quality service and clear communication throughout every project. With the personalized attention of a dedicated team and the expertise of a large contractor, Best Roofing has earned recognition as a trusted partner for South Florida’s community associations, property managers, and commercial property owners.

For the Cypress Pointe at Turtle Run project, Best Roofing collaborated with Polyglass USA to complete a comprehensive roof replacement across all 34 buildings. The team began by applying Polystick TU Max, a self-adhered waterproofing underlayment renowned for its durability and reliability in securing roof tiles. This step ensured a watertight foundation for the installation of Spanish-style concrete roof tiles.

Additionally, PG 500, a versatile cold-applied bonding agent, was used. Its thick, trowel-grade consistency made it ideal for detailed work such as attaching membranes to steep slopes and parapet walls, as well as handling various waterproofing repairs.

One of the highlights of this large-scale project, according to Zachary Towers, Vice President of Business Development at Best Roofing, was the dependability of Polyglass roofing materials. The underlayments allowed the roofing contractors to safely and efficiently remove the old roofs from all 34 buildings without any delays. “We knew every square foot of the 270,000 square feet of roofing was secure and watertight while we worked,” Towers explained.

“Polyglass underlayments have become our go-to system because of their easy installation, quality, and consistency. Polystick TU Max gives us and our clients peace of mind,” Towers added.

By the Numbers

Location

6476 W. Sample Rd.

Coral Springs, Florida

Size

270,000 square feet

Product Spotlight

Polystick TU Max

Polystick TU MAX is a high-performance, self-adhered waterproofing underlayment designed for adhesive foam or mechanically fastened roof tile applications. Utilizing ADESO® dual-compound self-adhered technology, it combines a polymer-modified bitumen upper layer with a proprietary SBS (elastomeric) self-adhesive compound on the underside. This combination ensures exceptional performance, with a split-release film that simplifies installation.

Engineered for versatility, Polystick TU MAX is ideal for steep-slope applications, including tile, slate, and other roof coverings. It also serves as effective reinforcement for perimeter and flashing details, making it a multi-purpose solution for demanding roofing needs.

Designed for high-temperature environments, Polystick TU MAX can withstand exposure for up to 180 days (or as limited by local building codes), making it a reliable choice for various roofing applications.

Flexibility is another key advantage of Polystick TU MAX, allowing it to lay flat with ease and significantly speed up installation. Its patented SEALLap® adhesive treatment at membrane overlaps ensures a quick, watertight bond. While primarily designed for concrete and clay tiles, it can also be integrated into a multi-ply system when used with Polystick MTS PLUS, offering enhanced durability and versatility. Polystick TU MAX should not be applied directly over existing asphalt shingles or roof coverings.

PG 500

PG 500 is a premium, cold-applied bonding agent designed for SBS roofing systems and various other membrane systems. Its heavy, “trowel-grade” consistency makes it ideal for a wide range of applications. It can be used to apply SBS-modified bitumen membrane flashing to parapet walls, curbs, and roof penetrations. The product is also effective for sealing lap seams and perimeter edges of SBS-modified bitumen membranes and for topical applications on smooth or granule APP products during roofing repairs.

Additionally, it is ideal for repairing splits, breaks, and small holes in asphalt-based roofing and flashings, and for installing metal edge flanges or other metal joints. PG 500 is also useful for positive-side damp proofing of concrete and masonry walls or foundations. However, it is not recommended for use with thermoplastic or thermoset membranes.

This product offers several key benefits that set it apart from traditional plastic cements. Its superior flexibility accommodates the expansion and contraction caused by temperature fluctuations in roofing systems. With exceptional bonding strength, PG 500 ensures reliable adhesion in various applications. It delivers excellent weathering characteristics, performing well across challenging temperatures and weather conditions without mudcracking. The product remains highly flexible, resilient, and durable through all seasons, making it a reliable choice for long-term performance.

PG 500 eliminates the need for kettles and torches, offering a safer and more convenient application process. Its interlocking fiber matrix guarantees uniform adhesion, even on vertical surfaces at high temperatures, where it exhibits exceptional flow resistance. Furthermore, it is non-destructive to asphalt-based roofing membranes and made with 100% recycled cellulose fibers, ensuring an asbestos-free, environmentally responsible solution.

By combining durability, ease of use, and adaptability, the PG 500 is the ideal choice for a variety of roofing and waterproofing challenges.