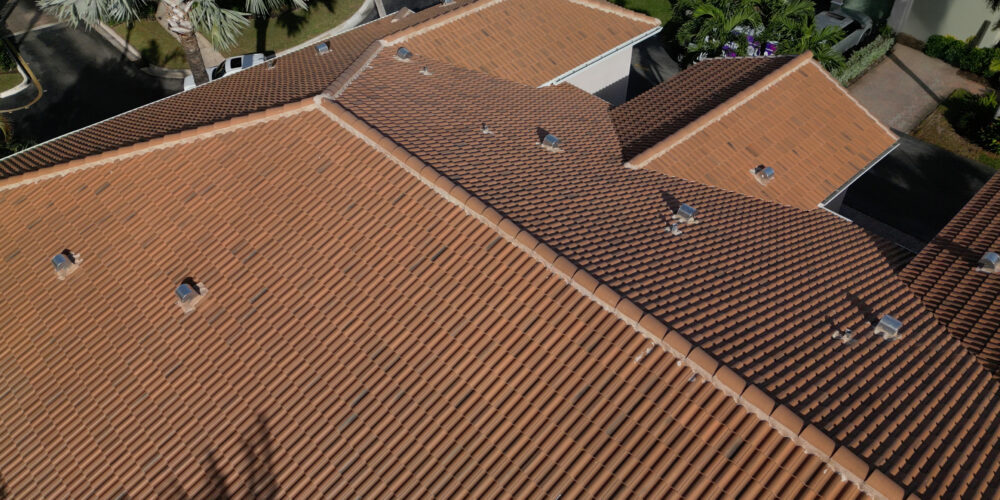

The Las Brisas townhome community in Hypoluxo, Florida, is a private, gated community featuring 95 luxury townhomes on a picturesque waterfront. Built in 2001, this exclusive enclave offers residents private beach access and a heated pool, creating a serene environment for elevated living. However, after 23 years, the townhomes required one key update to maintain the community’s high standard of luxury—new roofs. Best Roofing, a premier roofing contractor known for quality products, fair pricing, and exceptional customer service, was selected for this extensive project.

Established in 1978, Best Roofing is dedicated to understanding client needs and building strong professional relationships. They provide a seamless, stress-free workflow, delivering quality service and clear communication throughout every project. With the personalized attention of a dedicated team and the expertise of a large contractor, Best Roofing has earned recognition as a trusted partner for South Florida’s community associations, property managers, and commercial property owners.

To bring this project to life, Best Roofing partnered with Polyglass USA, leveraging premium roofing systems to ensure durability and longevity for the Las Brisas community.

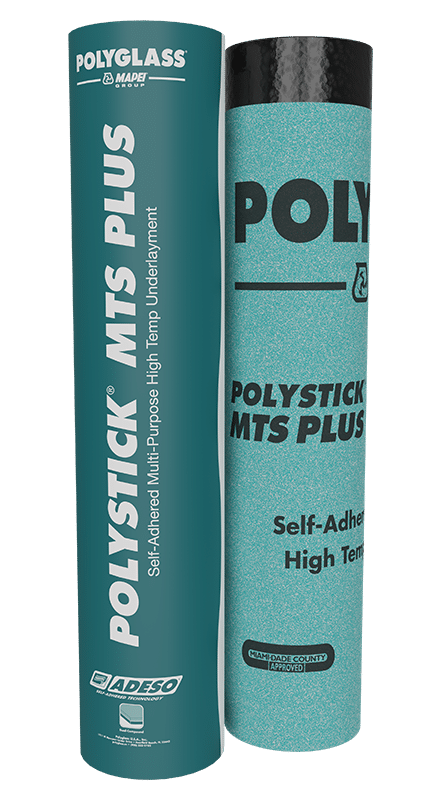

The installation process began with a complete tear-off of the old roofing materials down to the roof deck. The Best Roofing team then installed Polyglass Polystick MTS Plus underlayment, a self-adhering waterproof layer affixed directly to the deck and secured with back nailing. Polystick MTS Plus, designed for high-temperature roofs, features advanced dual-compound technology with a fiberglass mat embedded within a modified compound. This underlayment also boasts a slip-resistant surface and a UV exposure rating of up to 180 days, making it a reliable choice for South Florida’s climate.

For the roof valleys, the team installed Elastoflex SA V, a premium self-adhered elastomeric base ply using ADESO® Dual-Compound Self-Adhered Technology. This product utilizes Styrene-Butadiene-Styrene (SBS) modified asphalt on the top layer and an aggressive self-adhesive on the bottom, ensuring excellent stability with a reinforced fiberglass mat. Elastoflex SA V provided the necessary dimensional stability and flexibility for effective valley protection.

Finally, Polystick TU Plus was applied over the Elastoflex SA V. This dual-reinforced, self-adhered underlayment is designed for adhesive foam or mechanically fastened roof tile applications. Utilizing ADESO® dual-compound technology, Polystick TU Plus includes a UV-resistant, polymer-modified bitumen upper compound, along with a proprietary SBS elastomeric adhesive on the bottom, creating a robust and durable underlayment solution.

By the project’s completion in the fall of 2024, both homeowners and the Best Roofing team were highly satisfied with the results.

Zachary Towers, Vice President of Business Development at Best Roofing, expressed his appreciation for Polyglass, noting:

“Polyglass provided us with a responsive customer service team and readily available materials that were easy to install. This project ran smoothly and met the required codes and specs. We were able to offer our clients a superior product and longevity on a roof with the warranties provided by Polyglass. The SA V flashing strips are also a time and labor saver; wherever metal is installed, these flashing strips allow us to complete production more quickly and efficiently.”

Through its dedication to quality and strong partnerships, Best Roofing continues to elevate standards in roofing, ensuring that communities like Las Brisas retain their luxury appeal for years to come.

By the Numbers

Location

Las Brisas Circle

Hypoluxo, Florida

Size

180,600 square feet

Product Spotlight

Polystick MTS Plus

Polystick MTS PLUS is a premium self-adhered waterproofing underlayment designed for high-temperature roofing applications, including metal, concrete, and clay tiles. Manufactured using the patented ADESO® dual-compound self-adhered technology, this underlayment combines a polymer-modified bitumen upper compound with a proprietary self-adhesive SBS (elastomeric) compound on the bottom. The membrane features a split-release film that protects the self-adhesive compound, ensuring a smooth and efficient installation process.

This high-performance underlayment is equipped with a cavitated anti-skid top film surface, enhancing both its durability and ease of installation. It offers a temperature resistance of up to 265°F, making it particularly suitable for high-temperature roofing systems, such as steel, aluminum, or copper panels. Polystick MTS PLUS is approved for exposure of up to 180 days, ensuring long-lasting protection even during extended installation periods.

Elastoflex SA V

Elastoflex SA V is a high-quality, self-adhered elastomeric base ply roofing membrane, crafted using the patented ADESO® Dual-Compound Self-Adhered Technology. This innovative process involves applying a “true” Styrene-Butadiene-Styrene (SBS) modified asphalt compound to the top layer, while an aggressive self-adhesive compound is applied to the underside for superior bonding performance. The membrane is reinforced with a high-performance fiberglass mat, providing excellent dimensional stability and ensuring long-lasting durability.

The top surface of the Elastoflex SA V membrane is finished with either sand or a polyolefin film that includes laylines, offering enhanced protection and easy installation. The bottom surface features a split release film, ensuring a smooth application process by facilitating the removal of the protective layer.

Polystick TU Plus

Polystick TU Plus is a self-adhered, dual-reinforced waterproofing underlayment designed for both adhesive foam and mechanically fastened roof tile applications. Built with ADESO® dual-compound self-adhered technology, this underlayment features a UV-resistant polymer-modified bitumen plastomeric upper compound and a proprietary self-adhesive elastomeric Styrene-Butadiene-Styrene (SBS) compound on the bottom, ensuring superior waterproofing and long-lasting durability. The self-adhesive design allows for a quick and easy installation process, providing effective protection for a variety of roofing systems.

The membrane is reinforced with both an internal fiberglass mat and a high-strength polyester fabric surface, offering excellent puncture resistance and dimensional stability. It is engineered for use in high-temperature environments, up to 265°F, and is suitable for installation under clay, concrete, or slate tiles, as well as metal roof coverings.

Polystick TU Plus can also be used as part of a multi-ply underlayment system when installed over Polystick MTS Plus for enhanced performance. With its exceptional resistance to harsh conditions and superior slip resistance, Polystick TU Plus is an ideal solution for high-performance, long-lasting roofing systems.