The state-of-the-art water treatment plant in Mankato, Minnesota, processes up to 12 million gallons of water daily, producing approximately 1.7 billion gallons of drinking water annually for 13,487 service connections. This ensures Mankato residents can rely on clean and safe water every day of the year.

Maintaining the reliability of this system is essential. When the two-layer coating system on the top of the finished water tank began to deteriorate, finding a durable and efficient solution became a top priority.

The original coating system, consisting of a silicone base with an acrylic top layer, was no longer performing effectively. The city needed a long-lasting, fully warranted replacement to ensure the tank’s continued performance.

Greener World Solutions LLC: The Chosen Experts

Greener World Solutions, a family- and woman-owned business with over 50 years of experience, specializes in coating, waterproofing, roofing repair, maintenance, and insulation services for commercial and residential properties in Waseca, Minnesota, and surrounding areas. Their extensive expertise and commitment to quality made them the ideal choice for the Mankato water tank project.

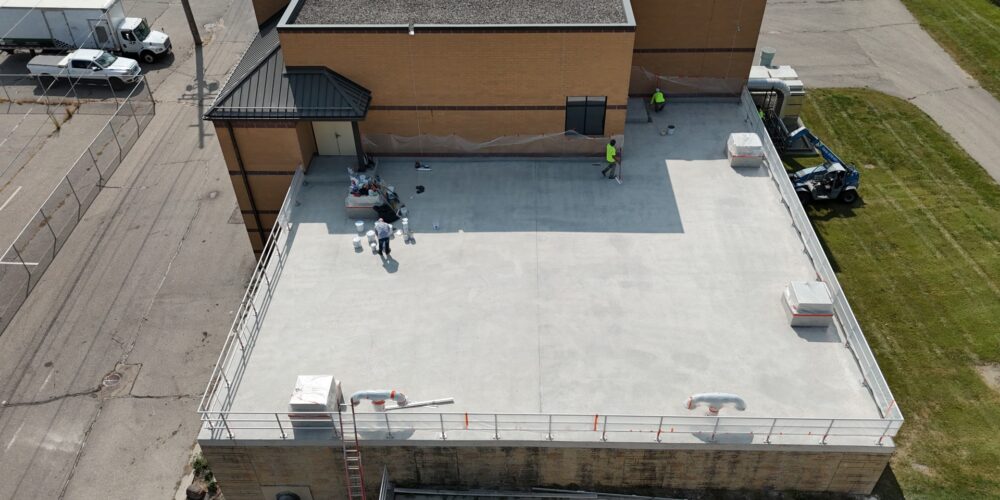

The team’s mission was clear: to ensure that the concrete top of the drinking water storage tank was impervious to contamination. This required a meticulous approach, as the project presented significant challenges, including exposure to harsh elements and completion during the rainy season. These factors made moisture infiltration a substantial risk, necessitating a fast-drying, high-performance coating solution.

Project Challenges and Innovative Waterproofing System Solutions

Greener World Solutions encountered several challenges during the project, including a substrate exposed to harsh environmental conditions and the need to complete the work swiftly to prevent moisture intrusion. While traditional epoxy systems could have provided adequate performance, their slower application process was unsuitable for the project’s demands.

To address these issues, Greener World Solutions collaborated with Polyglass USA to leverage their advanced TecnoCoat product line. The selected system included:

- TecnoCoat EP-1010 primer

- TecnoCoat P-2049 polyurea membrane

- TecnoTop 2C polyurethane topcoat

The TecnoCoat P-2049 pure polyurea membrane, with an impressive set time of just 7 seconds, proved to be the ideal solution. Unlike traditional epoxy/urethane systems, typically applied at 24 mils across multiple coats, the P-2049 membrane was applied at 100 mils in a single coat. This innovative approach, utilizing a liquid waterproofing membrane, delivered exceptional waterproofing performance, significantly reduced the project timeline, and remained cost-effective.

Detailed Project Timeline

The project was successfully completed in just three and a half days through meticulous planning and execution:

- Day 1: Removal of the existing coating layers.

- Day 2: Application of TecnoCoat EP-1010 primer and crack filling to ensure proper adhesion.

- Day 3: Application of the TecnoCoat P-2049 polyurea membrane and base coat.

- Day 4: Application of the TecnoTop 2C topcoat.

This streamlined and efficient process showcased the remarkable results achievable by pairing expert application techniques with cutting-edge materials.

Contractor Insights and Benefits

“Collaborating with Polyglass team we implemented a robust, specification-compliant solution,” said Philip Bulfer, owner and managing partner of Greener World Solutions. “This innovative system not only ensures durability but also facilitates straightforward inspections and maintenance.”

“The support from Polyglass was exceptional, enabling timely, high-quality project execution.”

The project’s success highlights the importance of selecting the right materials and partners for critical infrastructure. The TecnoCoat system not only ensured immediate waterproofing by forming a waterproof layer but also promised long-term reliability. Mankato’s leaders and residents can now depend on clean, safe drinking water for years to come.

By the Numbers

Location

Mankato Water Treatment Plant, Mankato, Minnesota

Size of Concrete Surfaces

5,000 square feet

Challenges of Water Penetration

- Ensuring the concrete slab and foundation walls were impervious to prevent contamination of the drinking water below.

- Completing the project quickly during the rainy season to avoid moisture exposure.

Product Spotlight

TecnoCoat EP-1010 Liquid Waterproofing Membrane Primer

A two-component epoxy primer designed to enhance adhesion between the substrate and TecnoCoat membrane systems. Its high bonding capability ensures a strong foundation for subsequent layers.

TecnoCoat P-2049 Pure Polyurea Membrane

The TecnoCoat P-2049 Pure Polyurea Membrane is a high-performance, two-component, fast-setting solution designed for superior waterproofing and traffic coating applications. With its spray-applied method, the membrane creates a seamless, fully bonded surface that cures rapidly, forming a monolithic layer ideal for use in demanding environments. Engineered for exceptional durability, it withstands mechanical stress while offering outstanding chemical resistance and elasticity, even in extreme conditions.

This innovative membrane provides an effective solution for a variety of industries and surfaces, including sloped or flat walkable roofs, concrete decks, parking garages, and foundations. With a tack-free time of just 12 seconds and the ability to be foot trafficked within minutes, the TecnoCoat P-2049 ensures quick, reliable application. Its low VOC content, ease of repair, and compatibility with various topcoats further enhance its appeal as a durable, long-lasting waterproofing solution.

TecnoTop 2C Topcoat

TecnoTop 2C is a two-component polyurethane topcoat with chemical and UV resistance, ideal for both vehicular and pedestrian traffic. It provides a protective layer for TecnoCoat systems, ensuring weatherability for applications exposed to permanent weather conditions.