Headquartered in Wixom, Michigan, Schreiber Roofing Corporation is a fifth-generation, family-owned commercial roofing company that has been in business since 1916. When Schreiber Roofing was tapped to perform a commercial roofing project on Fiat Chrysler Automobile’s (FCA) Mack II engine plant in Detroit, MI, they chose to use Polyglass roofing products as the optimal solution for the project’s unique challenges.

As a 100-year-old roofing company with a long track record of success, Schreiber Roofing felt that Polyglass products were the best fit for the cold-weather profile of the plant.

Meeting the Challenges of a Cold-Weather Roofing Project

Located in Detroit, MI, the Mack Avenue Engine Plant Complex has been owned by the Chrysler Corporation (now FCA) since 1953, when they purchased it from the Briggs Manufacturing Co. Since 2019, the plant has been under reconstruction as the future assembly site for several models of Jeep vehicles, including the next-generation Jeep Grand Cherokee.

Schreiber Roofing was called upon to do a commercial re-roofing as part of this ongoing construction. However, the project presented several environmental challenges and restrictions to be worked through. “We were under extreme weather/temperature restrictions and needed a product that could be installed at low temperatures,” says Polyglass rep James Gosiaux. “The product had to be solvent-free, and no torches were allowed on site.”

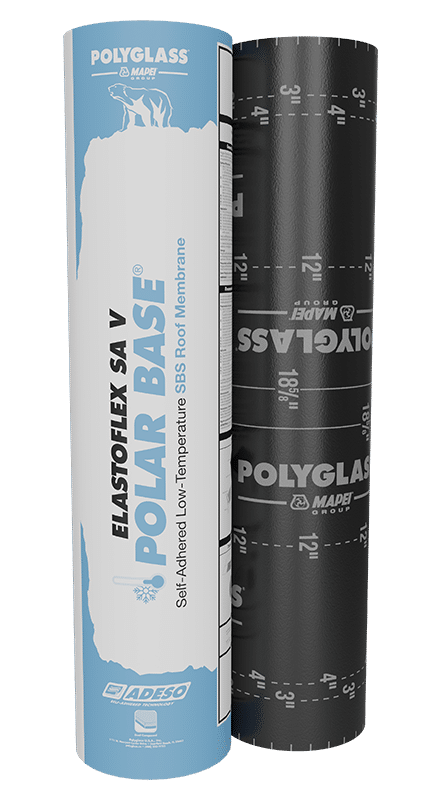

To meet these challenges, the Schreiber team first removed the existing roof system to the steel deck, then installed multiple layers of ISO insulation and a cover board. They finished the outer layers of the roof using Polyglass Elastoflex SA V Polar Base and Elastoflex SA P Polar Cap, which are solvent-free and rated for cold temperature installation.

These low-temperature SBS roofing membranes are perfect for cold weather applications ranging from 25–60ºF (-4–16ºC). The base sheet is built with a high performance reinforced fiberglass mat for excellent dimensional stability, while the cap sheet consists of a granule surface and a reinforced polyester mat for excellent puncture and tear resistance.

Both products feature Polyglass’ patented ADESO® Dual-Compound Self-Adhered Technology, eliminating the need for torches or hot asphalt during application.

Apply to be a Registered Polyglass Contractor

Schreiber Roofing’s reputation for quality is built on high standards of excellence and craftsmanship due to their team of 100 all-union roofers, each of whom must train for four years before reaching journeyman status. They also insist on using only the highest-quality roofing products for their roofs, which is why Schreiber Roofing is a Registered Polyglass Contractor.

If your roofing company has not yet become a Registered Polyglass Contractor, we invite you to take advantage of this opportunity. Registered Contractors receive the inside scoop on the latest Polyglass products and technologies, along with a series of discounts and loyalty rewards. In addition, your company is listed on our website’s contractor search page, which adds credibility and provides more exposure for your company. To apply to become a Registered Polyglass Contractor, click here.